When a leading HVAC equipment manufacturer found its assembly line bottlenecked by slow manual riveting, they turned to Bead Electronics for a faster, smarter solution.

A Blind Rivet That Created an Assembly Line Stoppage

The manufacturer’s adjustable louver design relied on a blind rivet to secure the hinge mechanism in an aluminum extrusion. While effective, the blind rivet required several minutes per assembly due to tight manual alignment, creating costly delays and fatigue on a high-volume production line.

To stay competitive and pick up the pace, the customer needed a fastening method that could tolerate dimensional variation in the extrusion and install in seconds, not minutes.

The Solution: A Custom Square Pivot pin

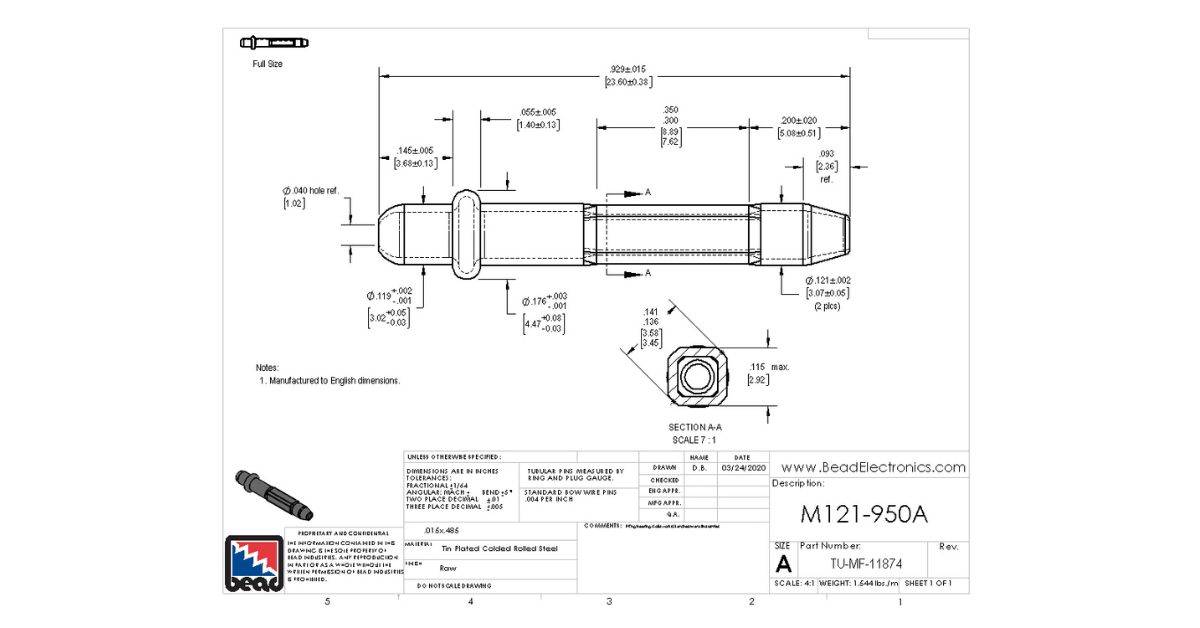

Leveraging our expertise in precision hollow pin engineering, Bead developed a press-fit rivet with a square cross-section: a unique geometry that provided at least three points of contact within the semi-circular hole of the aluminum extrusion.

This square design compensated for inconsistencies in hole size and shape, ensuring consistent retention and eliminating the need for blind-rivet tools. Operators could now simply press the pop rivet into place, reducing assembly time from minutes to seconds.

Engineering Collaboration and Iteration

Bead’s engineers fine-tuned multiple factors to balance retention strength, ease of assembly, and manufacturability:

- Fit & Tolerance: Optimizing interference fit to hold firm without deforming the extrusion.

- Geometry: Refining square-section dimensions for a consistent grip.

- Material: Selecting a tubular alloy that provides both formability and long-term durability.

Through iterative testing, the team achieved an ideal balance of secure retention with effortless press-fit installation.

The Results: Speed, Consistency, and Cost Savings

The new fastener reduced assembly time from several minutes to seconds, dramatically boosting production efficiency. It maintained reliable retention even across variable hole sizes, eliminated secondary fastening steps, and simplified operator training.

.png?width=1200&height=628&name=Untitled%20design%20(26).png)

Maximizing Precision Since 1914

By replacing a slow blind rivet with a custom square hollow pivot pin, Bead Electronics helped its HVAC customer achieve faster assembly, consistent quality, and lower production costs. This project demonstrates how Bead’s precision tooling, swaging expertise, and application-specific engineering empower manufacturers to improve performance and process efficiency.

Ready to Improve Your Assembly Process?

Partner with Bead Electronics to design a custom fastener tailored to your production needs. Contact us today or request a custom quote to get started.