When you manufacture HVAC louvers at scale, the small components add up fast. Louver pins may seem like simple hinge elements, but their material usage and assembly behavior directly influence your production cost, assembly speed, and overall performance.

Most OEMs rely on solid pins, a traditional choice that works, but costs more than it needs to. Bead’s custom-engineered hollow louver pins are designed specifically for HVAC registers and diffusers, and can reduce material usage by up to 60% while improving assembly efficiency and solving common fit challenges.

If you’re still using off-the-shelf solid pins, here’s why it may be time to rethink your standard.

Solid Pins vs. Bead Custom Hollow Pins: What Engineers Should Know

The Function

Every HVAC register or diffuser frame includes:

- Four perimeter sides

- A series of louvers that pivot on pins

- Manual or electronic airflow controls

Louver pins act as mechanical hinge points, allowing the blades to rotate smoothly. How the pin is designed affects:

- Airflow control consistency

- Assembly time

- Long-term durability

- Cost of production

The Problem with Standard Solid Pins

Standard pins are:

- Heavier

- More expensive to machine

- Often over-engineered for what the application actually requires

Many manufacturers also prefer low, flat rivet heads, but standard forming processes can’t always produce them, although this aesthetic impact is irrelevant once the pin is hidden inside the louver assembly.

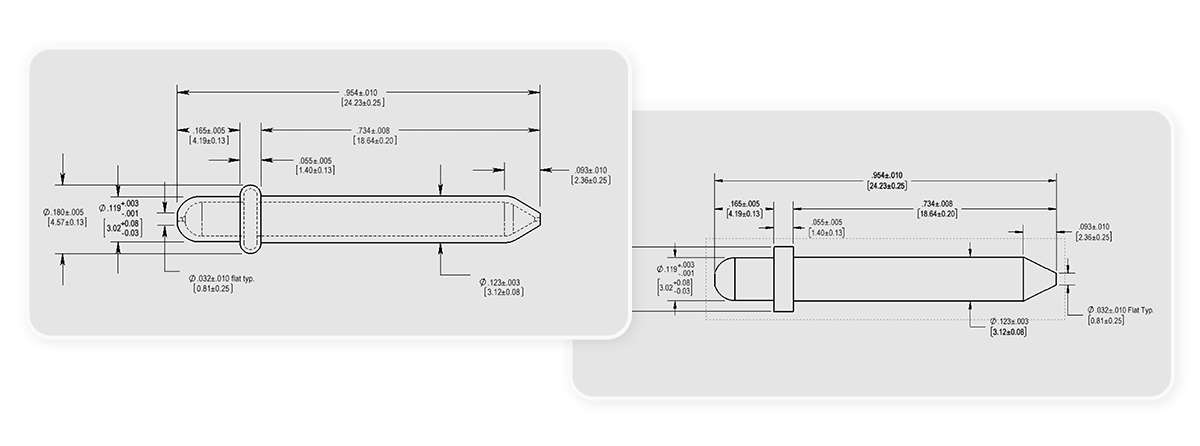

Bead’s Solution: Custom Hollow Louver Pins

Bead’s custom pins are engineered specifically for HVAC louvers. They include:

- A hollow interior that reduces weight and material

- A precision internal collar

- A short end designed to be “staked” or smashed during installation

- A lead-in tip geometry for smooth, fast blade assembly

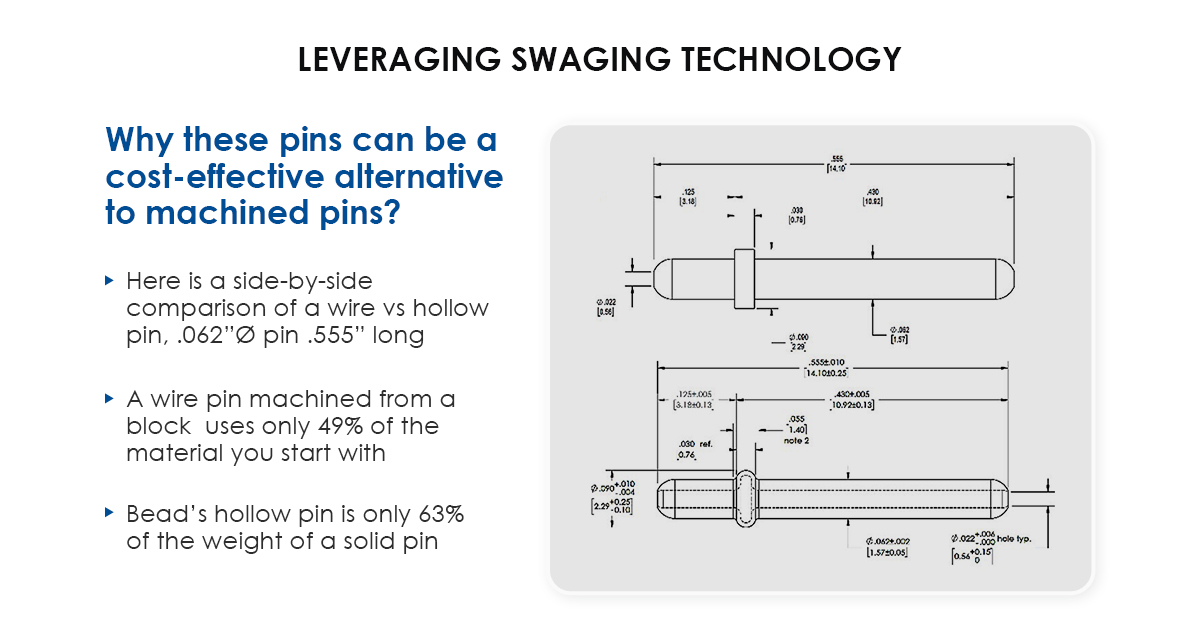

60% Material Savings—Backed by Real Numbers

When comparing Bead’s hollow pin to a standard solid pin:

- Hollow pin weight: 1.881 lbs./m

- Solid pin weight: 3.15 lbs./m

That’s a 60% reduction in tin-coated steel usage, which translates directly to:

- Lower material cost

- Lower freight cost

- Easier handling

- Less waste across high-volume production

This is the most significant cost lever available to HVAC louver manufacturers, and most are still leaving it untapped.

Designed for Fit, Function, and Real-World Variability

HVAC louvers aren’t uniform across every OEM. Two common scenarios exist:

Stamped Steel Louvers (Flexible Material)

- Material has enough “give” to work well with round hollow pins

- Hollow geometry reduces friction and preserves smooth pivot action

Extruded Aluminum Louvers (Rigid Material)

- The lack of flexibility can lead to fit issues with round pins

Bead solved this with square cross-section pins, engineered to seat reliably in zero-give geometries

Why Custom Pins Reduce Assembly Time

Bead pins are engineered with assembly in mind. Features include:

- Lead-in tip geometry = faster blade alignment

- Internal collar = precise seating without secondary processes

- Short stakable end = secure installation with minimal force

In high-volume production runs, these optimizations can eliminate thousands of unnecessary motions and seconds, translating to measurable labor savings.

Side-by-Side Comparison

When to Consider a Custom Louver Pin

You’re likely overspending if you currently experience:

- High material costs

- Heavy shipping weights

- Fit issues in rigid aluminum profiles

- Slow or inconsistent assembly

- Limited customization options

Bead’s custom pins are built to solve these exact problems without forcing a redesign of your existing HVAC registers and diffusers.

Final Takeaway: Stop Overspending on HVAC Louvers

In HVAC louver manufacturing, margins are tight, and solid pins drain material and labor budgets without adding functional value.

Bead’s hollow louver pins offer:

- Up to 60% material savings

- Less weight, lower cost

- Better assembly performance

- Custom geometry for any louver type

It’s a small part with a huge impact. You can learn more here.