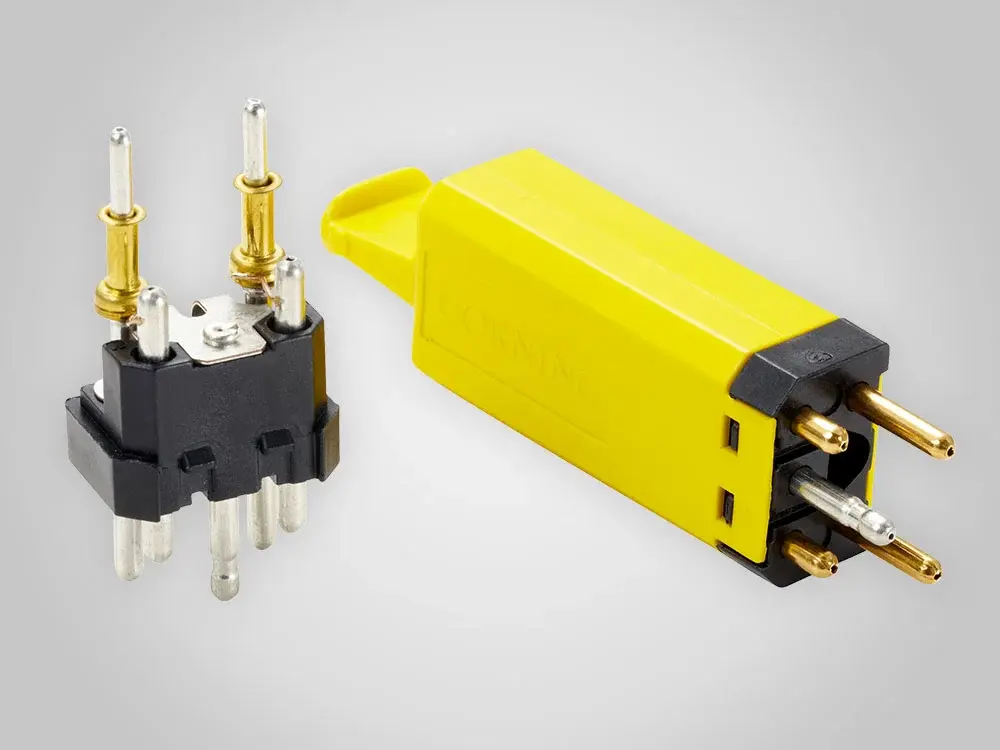

End-to-end contact pins, also known as continuous wire pins, work well as PCB connector pins. Manufactured with our wire-forming technology, our Tandem Pin® brand end-to-end contact pins come on continuous reels and can be installed using pin-insertion machines.