Controlled Precision

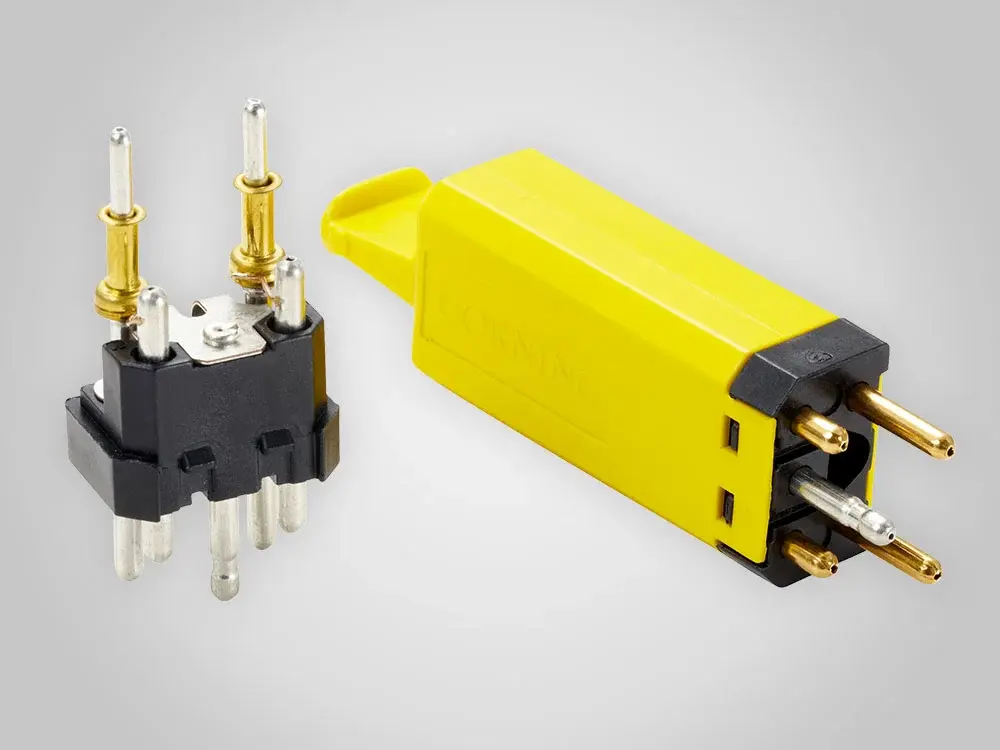

Bead’s Slimline Bulb Contact Pins are a specialty hollow pin created using staking. Staking is a mechanical technique used to hit the pin from one end. Compared to other techniques, staking requires less force and is a more controlled and consistent process.