Molds have revolutionized manufacturing - enabling suppliers to mass-produce identical parts in rapid succession. Injection molding, the process of injecting molten plastic into a mold to create a component, is widely used in the automotive, aerospace, industrial, and medical industries. Injection molding can be further broken down into two types: insert molding and overmolding.

What is Insert Molding?

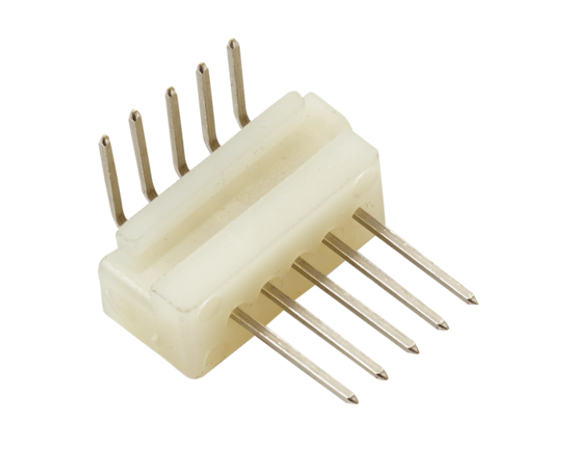

Insert molding is a manufacturing process where components are inserted into a mold before the plastic is injected resulting in a single bonded component. For example, threaded inserts are often molded into fasteners, while metal contact pins are inserts for connectors.

Using insert molding can reduce the cost of individual parts, eliminate the need for assembly, and maximize overall cost savings.

Insert molding also allows you to combine the cost-effectiveness, flexibility, and lighter weight of plastic with the strength and stiffness of metal, to make a more durable product.

However, if the components are custom and not off-the-shelf parts, this will add additional time and cost to the manufacturing process.

When to Use Insert Molding

You should consider using insert molding when your part needs:

- A metal component

- Threaded inserts

- A sub-assembly (embedded wires, electronic parts, or circuit board)

How to Use Insert Molding

Insert molding provides an opportunity to think outside the box. With components that can be mass-produced as a sub-assembly, like Right Angle Pin Headers, these products are easier to place into the molding machine, eliminating the need to individually place every contact pin. This results in a one-step insert process, saving time and money.

Regardless of how you plan to leverage insert molding, you need to make sure you have all your files ready for an engineer or designer to reference.

The final design must include insert CAD to see how much space the inserts occupy. This way, you get a comprehensive understanding of how your product’s structural integrity will be affected by these inserts. Any DFM required for the part will also need to be recorded so that the product’s quality is properly evaluated before its creation.

What is Overmolding?

Overmolding is essentially a type of insert molding, but in this case, the plastic is molded over another molded part. The first molded part is created in an injection mold and then inserted into a second mold to create the final product. This type of manufacturing is often found in handles, where a softer plastic is molded over the firm handle to make a more comfortable grip.

By combining multiple materials into one component, overmolding reduces assembly costs and eliminates the need for glue or other bonding agents. The various materials make an enhanced, more complex product with different textures, colors, or other properties. This technique is also useful when embedding soft seals into products.

Another example of using overmolding is creating pin assemblies. You can create one component with many pins instead of placing them at one time, saving time and ensuring the correct location.

However, if an optimal temperature is not maintained during the process, delamination could occur. Because overmolding requires two tools or a more complex two-shot mold, it is more expensive than molding a single part without overmolding. When faced with the decision of either making two injection-molded parts and assembling them or using overmolding, overmolding is more cost-effective.

When to Use Overmolding

You should consider using overmolding when the application requires properties such as:

- Different thermal or electrical properties

- Shock absorption or vibration-dampening

- Multiple colors

- A comfortable and non-stick grip

- Embedded soft seals

Overmolded parts can be further customized if needed.

The tremendous durability of overmolded components makes them a great fit for the automotive industry. For example, contact pins can be overmolded with plastic or rubber and used in connectors for vehicle sensors, control units or infotainment systems.

Making the right choice between insert molding and overmolding will depend on the specific requirements of your component. While insert molding is generally less expensive and faster, this may not be the case if you have to custom design a component.

Whether for overmolded and insert-molded connectors, or overmolded assemblies, Bead Electronics has a long history of providing pins for a variety of related applications in industries such as automotive, telecom, aerospace, industrial, medical, and more.

Bead's contact pins can be used for power, signal, or even electro-mechanical applications as part of an insert molded or over molded connector.

Contact us to speak to a specialist today!