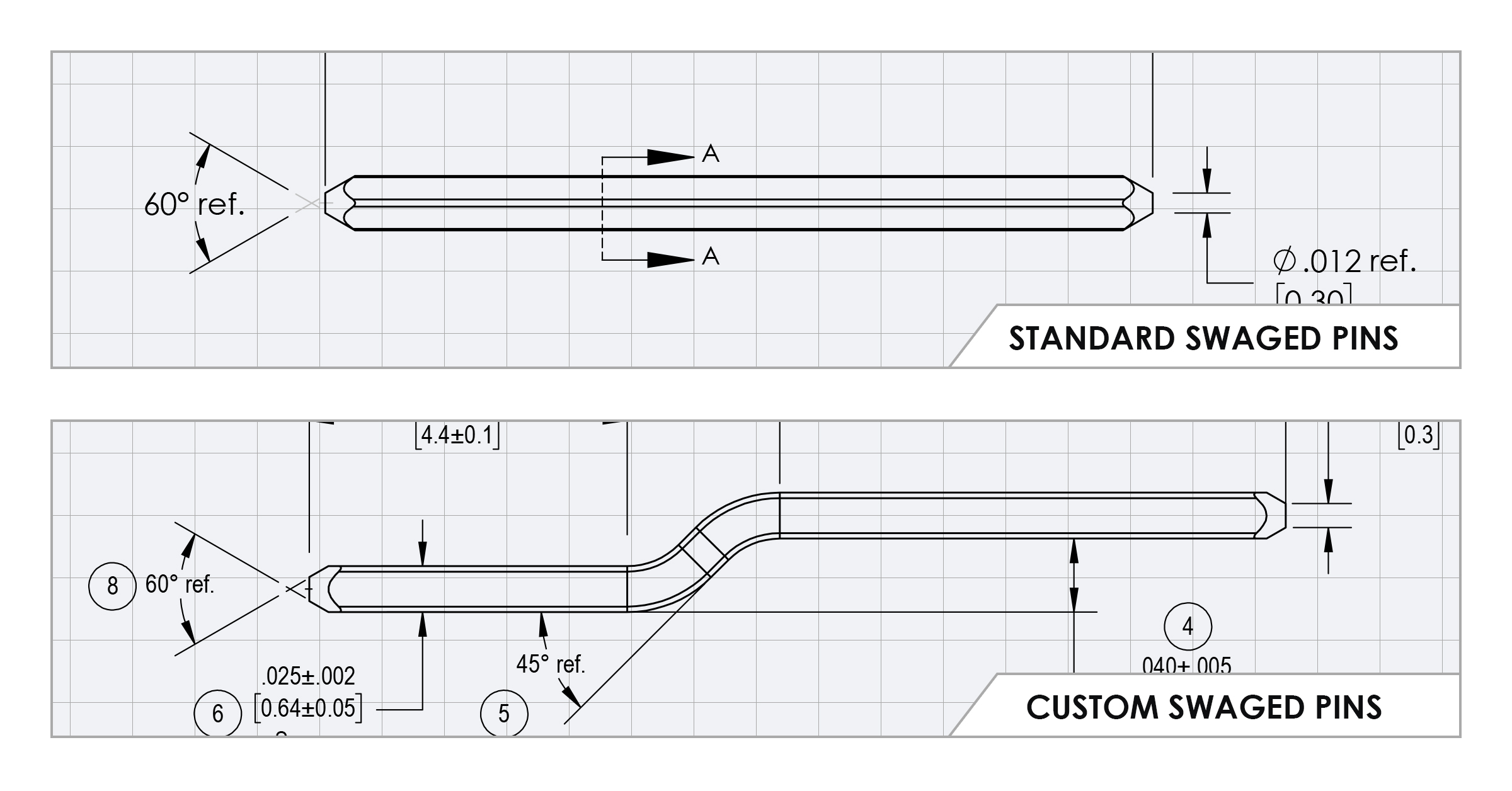

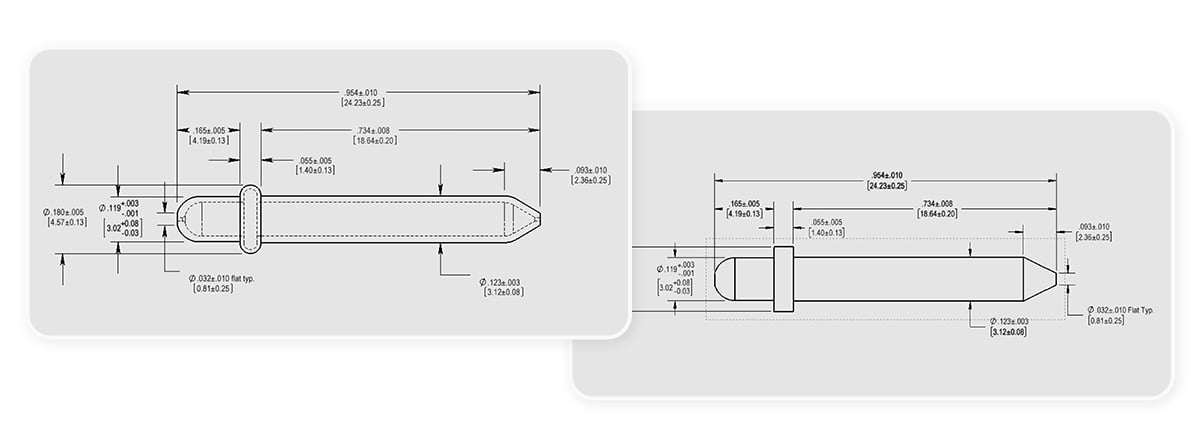

In precision electronics manufacturing, small improvements in process capability can create outsized gains in performance and cost efficiency. That’s why Bead Electronics’ recent investment in a next-generation swaging press represents more than a production upgrade. It’s a meaningful advancement in the engineering, manufacturing, and delivery of custom contact pins, with meaningful gains in speed and flexibility.

Read More

.png)